Carlson Grade For Drills

DRILL TO ELEVATION OR DEPTH WITH POWERFUL ACCURACY

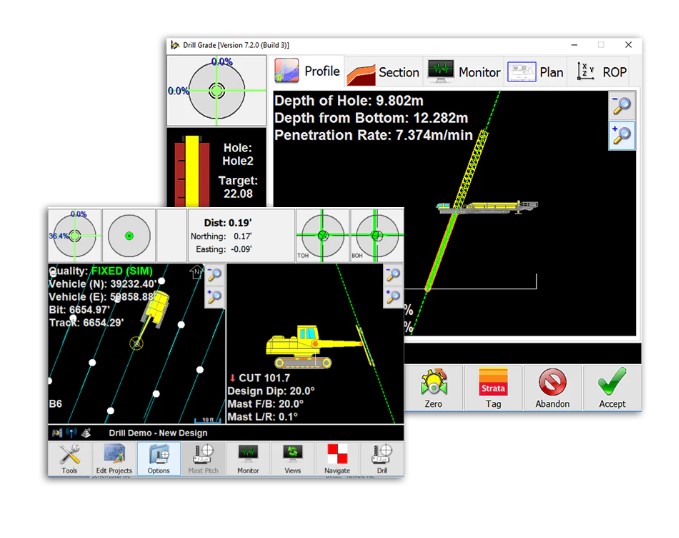

Carlson Grade for Drills allows drill operators to navigate and drill holes more precisely, increasing overall productivity. Carlson Grade reduces unnecessary survey costs and expenses associated with time in the field. It’s always the right time to improve your drilling workflow and operational efficiency.

KEY FEATURES

- Consistent user interface across all solutions

- Flexible and easy to use interface

- Multiple view options available in profile, section and plan

- Directly import from open CAD and Carlson platforms

- DWG, DXF, TN3, GC3, LN3, TIN, GRD

- Track machine utilization, downs and delays

- NTRIP and VRS compatible

- Able to handle large surface files

- Real-time machine system view and troubleshooting capability from anywhere in the world

- Peer to peer communication and information sharing capability between all machines

- Works as a stand-alone system or as part of a fleet environment with multiple machines

- Description

Description

SAFETY BENEFITS

- Increase operator situational awareness through proximity warnings between machines and fixed assets

- Increase operator awareness by utilizing 2D and 3D watch zones and warning zones

- Increase safety for surveyors and engineers by reducing survey time in the field

INTEGRATION WITH CARLSON COMMAND

Carlson’s complete monitoring and data management solution for machine control, Carlson Command, transmits data from machines to the office and from the office to machines in real-time. Command provides absolute oversight for site managers, allowing them to monitor multiple or single machines in a variety of viewing options from any remote location with an internet connection.

- Productivity analysis

- Data management of single or multiple sites

- Direct machine to machine communication and data sharing with live and historical 3D machine playback

- In-cab monitoring and training from office

- Full cut/fill color map with real-time surface updates

- Create and customize tasks, delays and down codes

For sites without remote connectivity, data can be stored in the machine for post-analysis.